Carli Extreme Duty Ball Joint Package 03-12 Ram HD

This special package from Carli Suspension saves you $100 when compared to buying the uppers and lowers seperately!

The LAST Ram Ball Joints You'll Ever Need to Buy

If you own a Ram HD and you’ve spent any time researching front end parts, it’s likely you’ve heard of Carli Ball Joints. Now that the research has begun and our customers are overloaded with information, what’s the benefit to these Carli Joints?

The main differentiators that matter – materials, process, and design. Our philosophy has always been to skip on the enumeration of materials and process. Leave this to the engineers way smarter than those of us within the organization who are put to the task of trying to destroy the products they design. As our lifetime ball joints have been in circulation for many years and more competition enters the market, the “what makes these so special” questions surfaces regularly; we’re happy to shed some light!

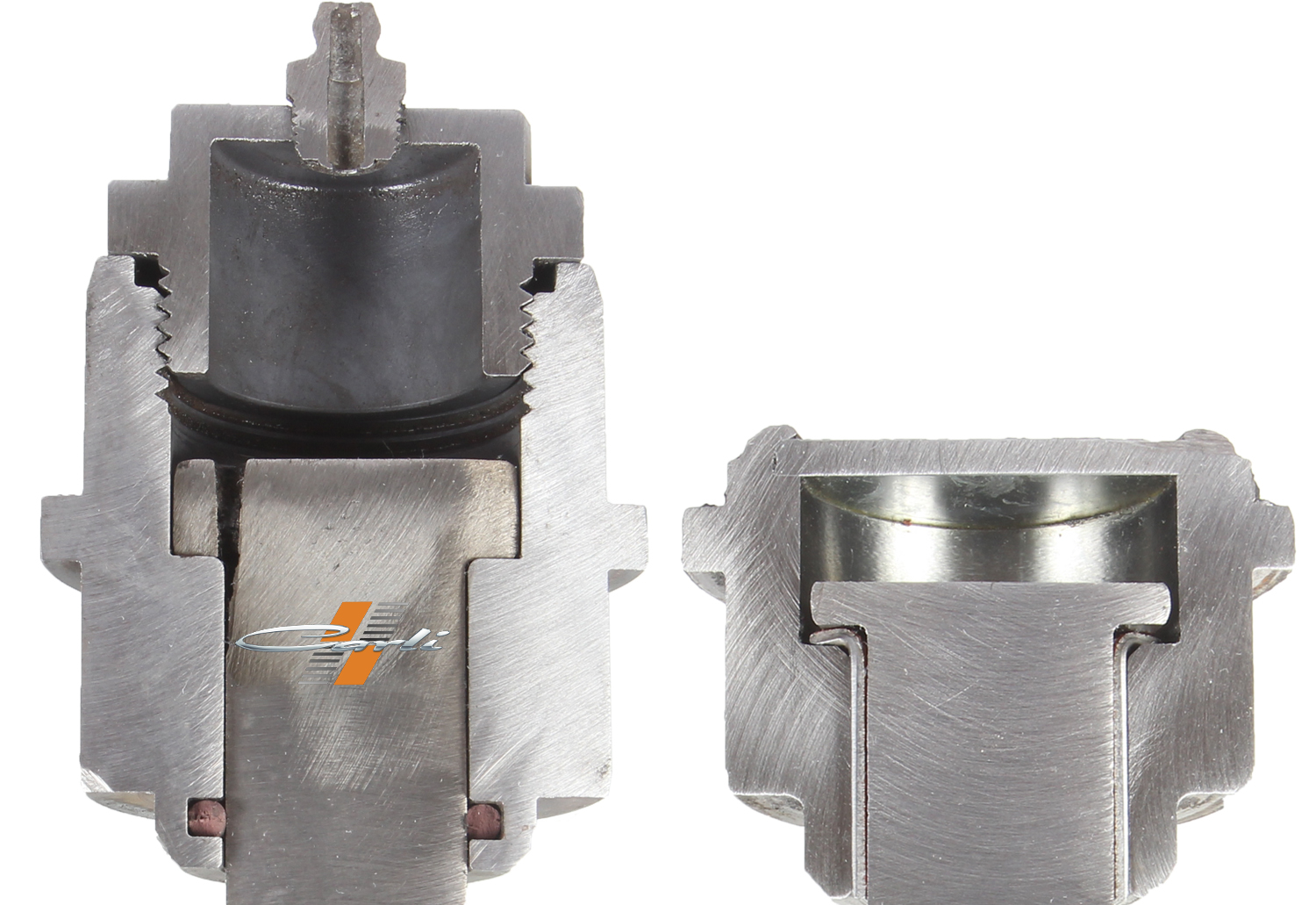

The design comes first. To know how we improved it, let’s take a look at the factory. The Factory Ball Joints are made up of a lower ball joint and upper floating king-pin. What better way to learn a product than to cut it in half to learn it’s functionality. The upper ball joint is designed as a pivot point determining the axis on which the knuckle will move and thus, only sees a lateral load. When you cut into the factory ball Joint, you find a sealed housing, sleeve, pin and boot. The upper cavity stores the grease from the factory and allows the “hat” of the pin to float up and down as the knuckle raises and lowers through the steering cycle. The “hat” of the pin does not make contact with the housing, it only prevents the pin from pulling out the bottom of the housing. As the hat of the pin doesn’t contact, there’s a coated sleeve that isolates the pin from the housing and it’s vertical surface is the only wear surface for the upper.

The Carli Joints are similar in design in that we utilize the same style of a floating King-Pin upper but with several improvements in design. You’ll notice our ball joint has a pin and housing but the “hat” of the pin contacts the housing. This adds a second wear surface to further distribute the load applied laterally to the ball joint while providing the same failsafe as a factory ball joint ensuring the pin cannot be pulled through the bottom of the ball joint housing. Further, there is no sleeve isolating the wear surfaces eliminating the point of failure. The upper cavity’s size is increased to hold a larger grease reserve and the threaded cap both allows access to the cavity and pin if needed and allows servicing through its zerk fitting. You’ll also notice the channel in the pin itself providing a path for grease to migrate to the wear surface. At the bottom of the housing, a Viton Seal prevents the environment from entering the ball joint.

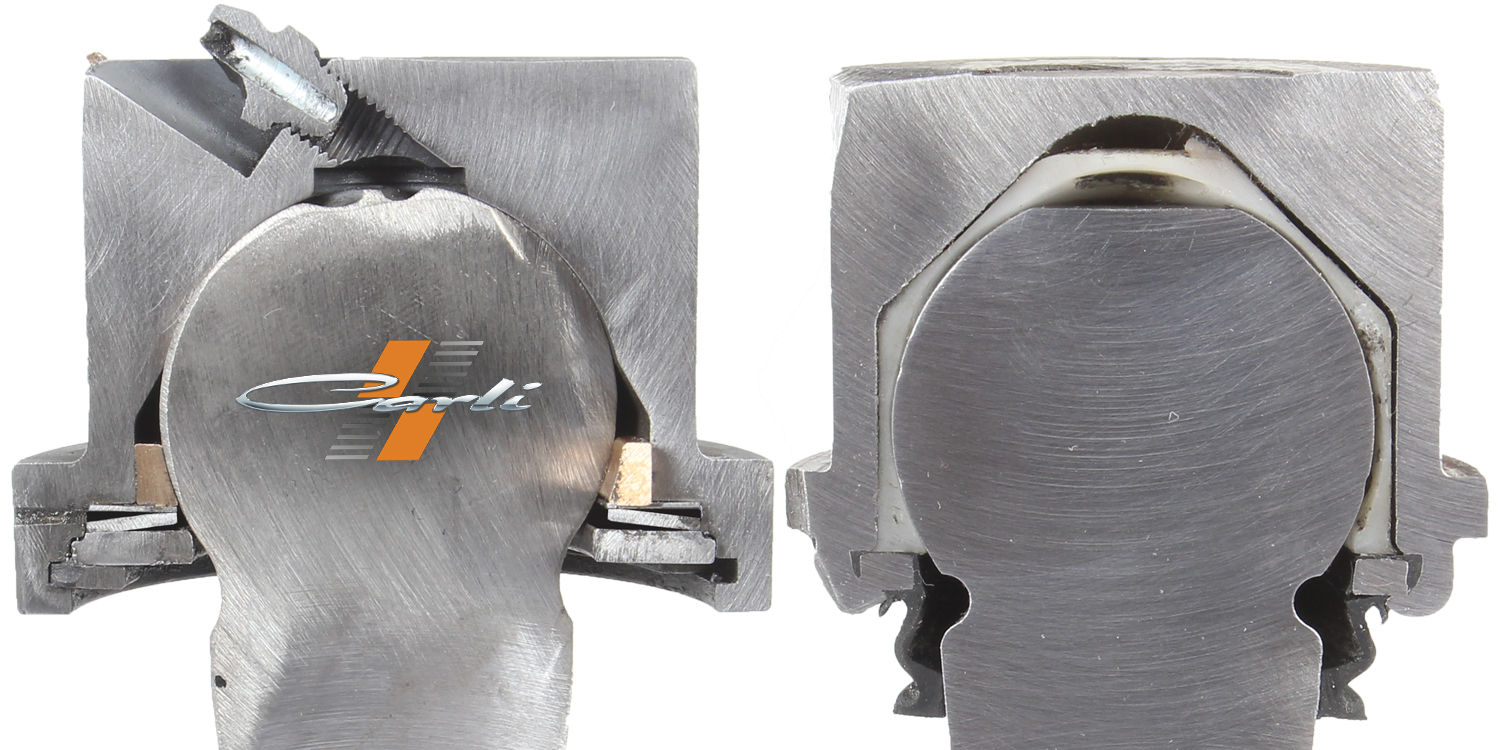

The lower ball joints are the true ball joints in the AAM design. The spherical lower is a ball and socket design allowing lateral misalignment (unlike the king-pin upper). Because the design tracks the knuckle on an imperfect axis, the spherical lower is required to allow the knuckle to move freely with only a slight vertical travel through its steering cycle. By design, the lower factory joint is a pin isolated from the housing by a nylon material loaded from the top and sealed by a press with a boot to keep out the elements. When this composite liner fails, the ball joint needs to be replaced. It’s the old saying, a chain is only as strong as its weakest link.

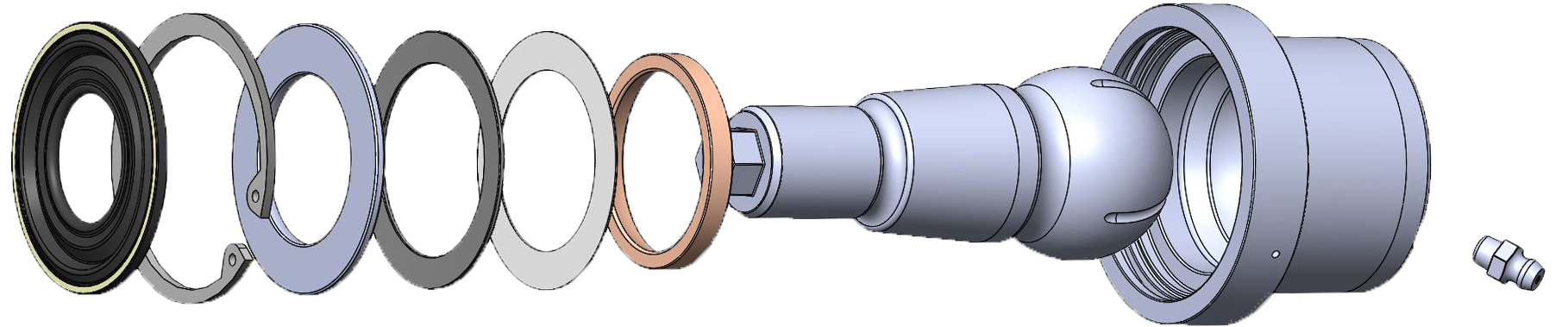

Our improvement on this design begins with the ability to service the joint. The Zerk fitting is recessed into the top of the joint and protrudes at an angle to be aimed forward and slightly inward to allow access to the fitting without needing to disassemble anything. In the cutaway, you can see the channels machined into our ball surface conducive to grease migration. Again, you’ll see no liners of any kind. At the top, a bronze wear surface preloaded by a disc spring, safety washer and snap ring ensures the ball joints wear surfaces are always held tightly together for optimal performance. Not shown in the picture but including in our lower is a rubber seal locking the housing to the pin.

Now that the design improvements are clear, why are we so confident in the materials that we think we can eliminate wear-surface isolation? We have tested every possible material and process to land where we have since the inception of these lifetime ball joints in 2007. Our process starts with masking. We mask the ball joints, all but the wear surface with a copper plating. Once plated, the ball joints head to carburizing. The carburizing creates an extremely hard surface with a case-hardness (penetrating depth) of 20-25 thousandths. For reference, another process we tried was salt-bath nitride which produced 3 thousandths in a best-case scenario. When the ball joint has completed the carburizing/heat treat, they’re stripped of their copper masking leaving the entire joint heat treated and the wear surfaces incredibly hard. From stripping, they head to dry-lube where the whole joint is coated with a corrosion resistant gray coating to project the joint while the lubricity of the coating pairs with ant seize and Redline CV2 grease to assist in breaking in the wear surfaces.

Normally, this is where you list the recipe of materials – well, we don’t want to spell out everything for the competition. The time we’ve put in (literal blood, sweat, tears) and hundreds of thousands of dollars to develop this indestructible product have led us to safeguard this recipe with our life. What we will do, back these ball joints with the industry’s only ADVANCED REPLACEMENT Lifetime Guarantee. Keep your purchase receipt and know you’re set for the life of the truck. If anything should happen, shoot us a video of the play (Excess of .040” vertical or .020” lateral) and your purchase receipt and we’ll have replacements enroute with a call tag to return the defective joints; simple as that. When you receive the new ones, swap them in and send the old ones back with the included call tag. It’s more expensive for us to do it this way and we end up replacing a lot of joints that either haven’t failed or were damaged by the installer but it’s a small price to pay to provide the best product and peace of mind that we’ll have our customer’s back regardless.

Warranty:

- Warrantied for life.

- In leu of enumerating the materials, processes and design characteristics of our Ball Joints, we're just going to stand behind this component for as long as you own it. If for any reason the performance of our Ball Joint declines, we'll stand behind it. For the life of your purchase. After the finalization of the R&D process we are confident that this part will never fail.

Extensive testing on the ball joints through Carli Suspension's product research and development cycle is now complete. We have logged thousands of nasty dirt miles over the past year to ensure that this product would be everything you have come to expect from us. These new Extreme Duty Ball Joints should yield a service life for as long as you own your truck and we're confident enough to offer a lifetime warranty. With an average labor of $500.00, the end user actually saves money the first time that they don't have to replace them.

Dodge Ram Upper Ball Joints

The ball joints start out as a chunk of 4130 chro-moly which is machined to our unique two tiered, internal grease port, patent pending design. The ball joint is then heat treated to a specified rockwell (hardness) that we have tested and set to make them able to withstand the meanest of beatings without showing any fatigue. From there the ball joints head to an aero-space lube company where a proprietary dry-lube is applied to our specified thickness. And of course we top them off with an accessible zerk fitting for easy servicing plus we even include a tube of high quality synthetic grease with each pair.

Upper Ball Joint Break In and Use

The ball joints are designed to break in after use. Constructed out of 4130, hardened and machined again makes for a smooth surface. With any hard smooth surface, there will be pores or high spots, not visible by the eye, but under extreme magnification you will be able to detect contact points raised from the general surface plain. The 2-stage aerospace dry lubrication process fills the pores of the machined surface and after significant period of time and consistant use, the surface will burnish. The definition of Burnish means to polish by friction. This is built into the design of the assembly and accounted for in the hard dry lubricant process. After removing the pin from the assembly following our testing periods, the surface has a luster to it which is the affect of the burnishing through normal use of the product. The burnished surfaces will reduce friction and smooth out rotation even further.

Without diving into a lesson on metallurgy, what we have discovered is that the ball joints get even better over time. Still flowing Redline CV2 high performance grease combined with the 2-stage machine applied dry lubricant process, the sheer pressure of the activity that the upper ball joint is subject to allows for the burnishing process to take place and when reviewed, you can see by eye and feel by touch that the surface is smoother. Just the way it was designed to do.

Dodge Ram Lower Ball Joints

Starting out from billet 4130 stock and CNC machined into a two-piece assembly, then case hardened, this truly is a bullet-proof component. The best part is the ride quality improvement over O.E.M. ball joints. The ball and socket on factory Dodge Ram Upper Ball Joints is separated by a plastic break-away that under severe stress, deflects.

By removing even .0625 inches of deflection times two axle ends omits 1/6" of an inch, or more, of ball joint deflection. You can feel it in the steering wheel. 35 and 37 inch tires, more stress and off-road impacts only exaggerate the movement, and subsequently, its affect. Your truck feels tighter and the steering wheel goes numb, even over pot holes and rail road tracks. The secondary tire movement, once eliminated, gives you a more controlled feel. Sometimes when you hit a sharp lip on the street, it feels like you hit two bumps, that aftershock is the tire's secondary movement from O.E.M. lower ball joint deflection. The front end of your truck will feel improved, or we'll buy the product back from you - guaranteed.

U-Joints

Replacing your ball joints? It is an opportune time to get at your U-Joints as well. Easily add the U-Joints you need to this order by selecting the correct U-Joints right up near the "Add to Cart" button. This means FREE SHIPPING on your ball joints and U-joints!

- 03 - 09 Dodge Ram - Spicer 5006813 U Joint

- 10 - 12 Dodge Ram - Spicer 5-3212X U Joint

SPECIFICATIONS:

- Heat Treated 4130 Construction

- 2-Stage Dry Lube Process

- Easy Maintenance

- Life Of The Vehicle Product

Whats Included

- 2 Upper Ball Joints

- 2 Lower Ball Joints

- LIFETIME WARRANTY

- Tube of CV2 Grease

- Lower Ball Joint Tool

DODGE RAM FITMENT GUIDE:

- 2003 - 2012 2500 / 3500 4x4

- 2013 2500 4x4 only - Will not fir the 2013 3500's!

- 2006 - 2009 1500 Megacab 4x4

- 2005 - 2013 Power Wagon

Upper and Lower Ball Joint Package Part Numbers

- CS-DBJP-03 | 03-12 Dodge Ram 2500/3500 4x4

- CS-DBJP-03 | 06-08 Dodge Ram 1500 4x4

Upper Ball Joints Part Numbers

- CS-DUJP | 03-12 Dodge Ram 2500/3500 4x4

- CS-DUJP | 06-08 Dodge Ram 1500 4x4

Lower Ball Joints Part Numbers

- CS-DLJP-03 | 03-12 Dodge Ram 2500/3500 4x4

- CS-DLJP-03 | 06-08 Dodge Ram 1500 4x4